B2B Online Store

| Technical Document: APP_GUIDE_IEC |

|

| Engineering package: DESIGN_CHECK_SYNC |

|

| Subscription Package: PREMIUM-Member_PACK |

IN-HOUSE-Workshop_PACK

In-house motor design workshop

Content: Practical application of the basic theory of electric machines and how to design them from scratch. Covering all aspects of the practical machine design process including sizing, pole, slot and winding selection, magnetic material selection, important mechanical issues, machine losses, efficiency, cooling aspects plus guidance with inverter types and sensor feedback.

Duration: two days at customer site.

Price: without travel expenses nor customization.

BIBLIO-Research_PACK

Bibliographic research (standard format)

Content: Three days of bibliographic research on a given topic using our comprehensive and dedicated library and other information sources. This will help you to locate, evaluate and use required information effectively.

Deliverables: Summary report with references and a first technical analysis.

QUOTE_PACK

Quotation

Content: According to your request we will prepare a formal technical and commercial quotation. The amount paid here will be deducted from your purchase price in case you order the corresponding service or product.

Deliverables: Formal quotation.

PREMIUM-Member_PACK

Premium member Subscription

Annual premium membership of motor-engineer.net with distinct access to our design experts.

Price: per annum

MENTORING-Junior_PACK

Mentoring Subscription Junior Level

You get one-to-one coaching with one of our technical experts – mainly by email, but if and when required by web meeting.

And this for as many hours as you decide.

MENTORING-Senior_PACK

Mentoring Subscription Senior Level

You get one-to-one coaching with one of our technical experts – mainly by email, but if and when required by web meeting.

And this for as many hours as you decide.

ACS-Standard_PACK

Annual Consulting Subscription Standard Package

This package gives continuous priority access to our engineering support and design services. The scope of work needs to be agreed in writing.

Content: five (5) man days to be used within 12 months from purchase.

ACS-Extended_PACK

Annual Consulting Subscription Extended Package

This package gives continuous priority access to our engineering support and design services. The scope of work needs to be agreed in writing.

Content: ten (10) man days to be used within 12 months from purchase.

ACS-Comfort_PACK

Annual Consulting Subscription Comfort Package

This package gives continuous priority access to our engineering support and design services. The scope of work needs to be agreed in writing.

Content: fifteen (15) man days, out of which ten need to be used within 12 months from purchase, and five can be carried over to the next twelve months period, if not used.

DESIGN_CHECK_SYNC

Feasibility and Checking of the Coil Distribution

Content: Verification of the different parameters of the machine as the winding and coil distribution. The main purpose is here to check the slot/pole combination and the winding arrangements.

Minimum requirements: Input Data for Synchronous Machine.

Deliverables: Winding Coil Distribution with Görges Diagram and MMF.

MODEL_FIRST_CALC_SYNC

Creation of 2D Model and Flux Density Distribution/Saturation analysis

Content: Creation of the model with geometry, winding description and physical properties. Both Analytical and Finite Element Method software are used to deal with the flux density distribution, normal flux density determination along the airgap and saturation analysis in the different parts of the machine: yokes, teeth, airgap…

Minimum requirements: Input Data for Synchronous Machine.

Deliverables: 2D Model, Screenshots of Flux Density Distribution and Values of Flux Densities at important parts of the machine and Airgap Flux Density curves.

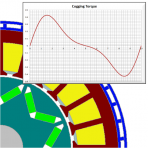

COGTORK_BEMF_SYNC

Cogging Torque and No Load Calculations

Content:

- Reluctance or Cogging Torque is determined and provided with curves and data,

- BEMF is determined and provided with curves, data and FFT Analysis.

Minimum requirements: MODEL_FIRST_CALC_SYNC.

Deliverables: BEMF Curve, Fourier analysis of BEMF. Cogging Torque Curve.

EQUIV_PARAMS_SYNC

Equivalent Parameters Determination

Content: By making a short circuit analysis and different calculations Equivalent Parameters are provided like Direct Reactance, No Load Flux and magnetizing curves of the Flux linkages/Inductances according to position and current values.

Minimum requirements: MODEL_FIRST_CALC_SYNC .

Deliverables: Short Circuit Current Value, Direct Reactance Value, Magnetizing Curves as Flux linkages according to position and Current Values.

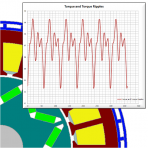

LOAD_CALCS_SYNC

Load Calculations with Torque Ripple

Content:

- Torque (mean torque and torque ripple) is computed for a given speed, current or voltage supply and phase advance value. 3 load points’ results (mechanical, electromagnetic and electric) are provided.

- These load calculations are computed by taking into account the thermal behavior of the machine. Thermal Analysis gives results as Temperature distribution for the steady state of the machine.

Minimum requirements: MODEL_FIRST_CALC_SYNC.

Deliverables: Power Balance with values of electrical and mechanical quantities (current, power factor, torque …) and curves of these quantities. Thermal analysis results with temperature distribution.

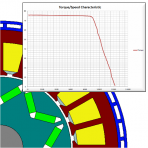

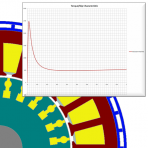

TS_ CURVE_SYNC

Torque/speed Characteristics

Content: Torque/Speed characteristics of traction machine for a given speed range and drive type (phase advance gamma values, one or more current values) are computed.

Minimum requirements: MODEL_FIRST_CALC_SYNC.

Deliverables: Torque/Speed curve and data of this curve.

THERM_DUTY_CYCLE_SYNC

Duty Cycle Thermal Analysis

Content: Thermal Behavior of the machine facing a duty cycle (either torque or speed duty cycle) is computed. Curves of the values of the temperatures at different parts of the machine are determined.

Minimum requirements: MODEL_FIRST_CALC_SYNC.

Deliverables: Thermal Curves for one duty cycle at different parts of the machines and Axial and Radial cross section of temperature distributions. All Data are provided.

FULL _CALC_SYNC

Radial Flux Synchronous Machine Full Package

Content: The full package of proposed calculations for Radial Flux Synchronous Machine.

Minimum requirements: Input Data for Synchronous Machine.

Deliverables: As per different package descriptions.

DESIGN_IMPROVE_SYNC

Design improvement proposal

Content: Topics are highlighted to improve the performances or dimensions of the design according to the customer’s requirements.

Minimum requirements: FULL _CALC_SYNC or complete data set provided by customer according to our specification.

Deliverables: Argumented list of design improvement avenues to be investigated.

DESIGN_CHECK_ASYNC

Feasibility and Checking of the Coil Distribution

Content: Verification of the different parameters of the machine as the winding and coil distribution. The main purpose is here to check the slot/pole combination and the winding arrangements.

Minimum requirements: Input Data for Asynchronous Machine.

Deliverables: Winding Coil Distribution with Görges Diagram and MMF.

MODEL_FIRST_CALC_ASYNC

Creation of 2D Model and Flux Density Distribution/Saturation analysis

Content: Creation of the model with geometry, winding description and physical properties. Both Analytical and Finite Element Method software are used to deal with the flux density distribution, normal flux density determination along the airgap and saturation analysis in the different parts of the machine: yokes, teeth, airgap…

Minimum requirements: Input Data for Asynchronous Machine.

Deliverables: 2D Model, Screenshots of Flux Density Distribution and Values of Flux Densities at important parts of the machine and Airgap Flux Density curves.

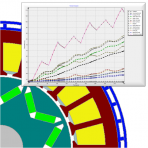

EQUIV_PARAMS_LOAD_CALCS_ASYNC

Equivalent Parameters Determination and Load Calculations

Content:

- Equivalent Parameters are provided for the induction machine as Inductances of the Stator and the Rotor, Resistances of the stator and rotor, Iron Resistance,…

- Torque is computed for a given slip, current or voltage .3 load points results (mechanical, electromagnetic and electric) are provided.

- These load calculations are computed by taking into account the thermal behavior of the machine. Thermal Analysis gives results as Temperature distribution for the steady state of the machine.

Minimum requirements: MODEL_FIRST_CALC_ASYNC.

Deliverables: Power Balance with values of electrical and mechanical quantities (current, power factor, torque …) and curves of these quantities. Equivalent Parameters Values, Thermal Analysis Results with temperature distribution.

TS_ CURVE_ASYNC

Torque/speed Characteristics

Content: Torque/Speed characteristics of traction machine for a given speed range and drive type (phase advance gamma values, one or more current values) are computed.

Minimum requirements: MODEL_FIRST_CALC_ASYNC.

Deliverables: Torque/Speed curve and data of this curve.

THERM_DUTY_CYCLE_ASYNC

Duty Cycle Thermal Analysis

Content: Thermal Behavior of the machine facing a duty cycle (either torque or speed duty cycle) is computed. Curves of the values of the temperatures at different parts of the machine are determined.

Minimum requirements: MODEL_FIRST_CALC_ASYNC.

Deliverables: Thermal Curves for one duty cycle at different parts of the machines and Axial and Radial cross section of temperature distributions. All Data are provided.

FULL _CALC_ASYNC

Radial Flux Asynchronous Machine Full Package

Content: The full package of proposed calculations for Radial Flux Asynchronous Machine.

Minimum requirements: Input Data for Asynchronous Machine.

Deliverables: The deliverables of the whole calculations.

DESIGN_IMPROVE_ASYNC

Design improvement proposal

Content: Topics are highlighted to improve the performances or dimensions of the design according to the customer’s requirements.

Minimum requirements: FULL _CALC_ASYNC or complete data set provided by customer according to our specification.

Deliverables: Argumented list of design improvement avenues to be investigated.

DESIGN_CHECK_AXM

Feasibility and Checking of the Coil Distribution

Content: Verification of the different parameters of the machine as the winding and coil distribution. The main purpose is here to check the slot/pole combination and the winding arrangements.

Minimum requirements: Input Data for Axial Flux Machine.

Deliverables: Winding Coil Distribution with Görges Diagram and MMF.

MODEL_FIRST_CALC_AXM

Creation of 3D Model and Flux Density Distribution/Saturation analysis

Content: Creation of the model with geometry, winding description and physical properties. Both Analytical and Finite Element Method software are used to deal with the flux density distribution, normal flux density determination along the airgap and saturation analysis in the different parts of the machine: yokes, teeth, airgap…

Minimum requirements: Input Data for Axial Flux Machine.

Deliverables: 3D Model, Screenshots of Flux Density Distribution and Values of Flux Densities at important parts of the machine and Airgap Flux Density curves.

BEMF_AXM

No Load Calculations

Content: BEMF is determined and provided with curves, data and FFT Analysis.

Minimum requirements: MODEL_FIRST_CALC_AXM.

Deliverables: BEMF Curve, Fourier analysis of BEMF.

FULL _CALC_AXM

Axial Flux Machine Full Package

Content: The full package of proposed calculations for Axial Flux Machine.

Minimum requirements: Input Data for Axial Flux Machine.

Deliverables: As per different package descriptions.

DESIGN_IMPROVE_AXM

Design improvement proposal

Content: Topics are highlighted to improve the performances or dimensions of the design according to the customer’s requirements.

Minimum requirements: FULL_CALC_AXM or complete data set provided by customer according to our specification.

Deliverables: Argumented list of design improvement avenues to be investigated.

APP_GUIDE_IEC

Applying IEC standards to Industrial Power Distribution Systems and Equipment

North American and Pacific Rim engineers with ANSI/NEMA background who need to work with the International Electrotechnical Commission (IEC) Standards will encounter many sources of misunderstandings and pitfalls:

- misinterpretation of the applicable standards due to partial understanding,

- confusion by applying concepts of another standards system to IEC equipment,

- using values which have a different meaning in another standards system,

- incomplete specifications leading to incorrect options taken by manufacturers,

- using obsolete standards.

This Application Guide discusses these points in a “tutorial handout”-style from the general perspective looking down at the detailed equipment concerned.

You can select the whole guide or only the parts you are interested in.

The author, Mr. Terence HAZEL, is a Senior Member of IEEE and is Secretary and Technical Chair of the Petroleum and Chemical Industry Committee Europe (www.pcic-europe.com). He has co-authored and presented several papers and tutorials at technical conferences in North America, Europe, the Middle East and Asia. He has put more than 40 years of International Project Engineering experience into this 322 page guide.

Magnets

Theoretical and Practical Aspects of the Magnets for Electric Motors and Generators

Advantages and drawbacks of different types of magnets used in Electric rotating Machines Design from their theory and history to the modeling of these magnets and calculations like Cogging Torque, BEMF, Demagnetization…

Specification_CHKLST_REM

What to specify when buying an electric motor or generator?

This checklist enumerates a non-exhaustive list of points one should consider when specifying an electric motor or generator.

- General,

- Dimensions,

- Performances and prices,

- Characteristics,

- Thermal Performances,

- Control / Drives and Power Electronics.

Specification_CHKLST_POWELEC

What to specify when buying or designing a power electronics drive?

This checklist enumerates a non-exhaustive list of points one should consider when specifying a drive for an electric rotating machine.

- General,

- Dimensions/ Mounting,

- Drives and Control Interface/Sensors,

- Cooling.

3P_21KW_50Nm_DATASHEET

Brushless Permanent Magnet DC Machine

…designed and optimized for EHVs

- Dimensions,

- Performances,

- Torque/Speed characteristic,

- Efficiency map

- General characteristics,

- Advantages.