Synchronous Machine

DESIGN_CHECK_SYNC

Feasibility and Checking of the Coil Distribution

Content: Verification of the different parameters of the machine as the winding and coil distribution. The main purpose is here to check the slot/pole combination and the winding arrangements.

Minimum requirements: Input Data for Synchronous Machine.

Deliverables: Winding Coil Distribution with Görges Diagram and MMF.

MODEL_FIRST_CALC_SYNC

Creation of 2D Model and Flux Density Distribution/Saturation analysis

Content: Creation of the model with geometry, winding description and physical properties. Both Analytical and Finite Element Method software are used to deal with the flux density distribution, normal flux density determination along the airgap and saturation analysis in the different parts of the machine: yokes, teeth, airgap…

Minimum requirements: Input Data for Synchronous Machine.

Deliverables: 2D Model, Screenshots of Flux Density Distribution and Values of Flux Densities at important parts of the machine and Airgap Flux Density curves.

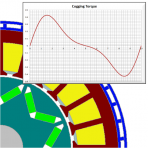

COGTORK_BEMF_SYNC

Cogging Torque and No Load Calculations

Content:

- Reluctance or Cogging Torque is determined and provided with curves and data,

- BEMF is determined and provided with curves, data and FFT Analysis.

Minimum requirements: MODEL_FIRST_CALC_SYNC.

Deliverables: BEMF Curve, Fourier analysis of BEMF. Cogging Torque Curve.

EQUIV_PARAMS_SYNC

Equivalent Parameters Determination

Content: By making a short circuit analysis and different calculations Equivalent Parameters are provided like Direct Reactance, No Load Flux and magnetizing curves of the Flux linkages/Inductances according to position and current values.

Minimum requirements: MODEL_FIRST_CALC_SYNC .

Deliverables: Short Circuit Current Value, Direct Reactance Value, Magnetizing Curves as Flux linkages according to position and Current Values.

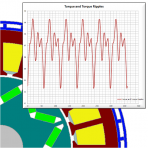

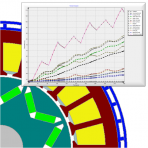

LOAD_CALCS_SYNC

Load Calculations with Torque Ripple

Content:

- Torque (mean torque and torque ripple) is computed for a given speed, current or voltage supply and phase advance value. 3 load points’ results (mechanical, electromagnetic and electric) are provided.

- These load calculations are computed by taking into account the thermal behavior of the machine. Thermal Analysis gives results as Temperature distribution for the steady state of the machine.

Minimum requirements: MODEL_FIRST_CALC_SYNC.

Deliverables: Power Balance with values of electrical and mechanical quantities (current, power factor, torque …) and curves of these quantities. Thermal analysis results with temperature distribution.

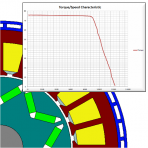

TS_ CURVE_SYNC

Torque/speed Characteristics

Content: Torque/Speed characteristics of traction machine for a given speed range and drive type (phase advance gamma values, one or more current values) are computed.

Minimum requirements: MODEL_FIRST_CALC_SYNC.

Deliverables: Torque/Speed curve and data of this curve.

THERM_DUTY_CYCLE_SYNC

Duty Cycle Thermal Analysis

Content: Thermal Behavior of the machine facing a duty cycle (either torque or speed duty cycle) is computed. Curves of the values of the temperatures at different parts of the machine are determined.

Minimum requirements: MODEL_FIRST_CALC_SYNC.

Deliverables: Thermal Curves for one duty cycle at different parts of the machines and Axial and Radial cross section of temperature distributions. All Data are provided.

FULL _CALC_SYNC

Radial Flux Synchronous Machine Full Package

Content: The full package of proposed calculations for Radial Flux Synchronous Machine.

Minimum requirements: Input Data for Synchronous Machine.

Deliverables: As per different package descriptions.

DESIGN_IMPROVE_SYNC

Design improvement proposal

Content: Topics are highlighted to improve the performances or dimensions of the design according to the customer’s requirements.

Minimum requirements: FULL _CALC_SYNC or complete data set provided by customer according to our specification.

Deliverables: Argumented list of design improvement avenues to be investigated.